From today’s perspective, vacuum tubes are pretty low tech. But for a while they were the pinnacle of high tech, and heavy research followed the promise shown by early vacuum tubes in transmission and computing. Indeed, as time progressed, tubes became very sophisticated and difficult to manufacture. After all, they were as ubiquitous as ICs are today, so it is hardly surprising that they got a lot of R&D.

Prior to 1938, for example, tubes were built as if they were light bulbs. As the demands on them grew more sophisticated, the traditional light bulb design wasn’t sufficient. For one, the wire leads’ parasitic inductance and capacitance would limit the use of the tube in high-frequency applications. Even the time it took electrons to get from one part of the tube to another was a bottleneck.

There were several attempts to speed tubes up, including RCA’s acorn tubes, lighthouse tubes, and Telefunken’s Stahlröhre designs. These generally tried to keep leads short and tubes small. The Philips company started attacking the problem in 1934 because they were anticipating demand for television receivers that would operate at higher frequencies.

Dr. Hans Jonker was the primary developer of the proposed solution and published his design in an internal technical note describing an all-glass tube that was easier to manufacture than other solutions. Now all they needed was an actual application. While they initially thought the killer app would be television, the E50 would end up helping the Allies win the war.

Television

In Britain, there was a single television transmitter at Alexandra Palace — the start of what would become the BBC. This was not only the first public television service but also the first fully electronic television system. Pye Ltd. — a company eventually bought by Philips — made receivers that were surprisingly successful. The sound was at 41.5 Mhz and the visual was at 45 MHz — high frequencies for those days.

Spurred by the demand, Pye decided that a set with more range would create a broader market for receivers. The problem was finding a tube that could handle the 45 MHz frequency in their tuned radio frequency (TRF) design.

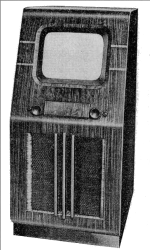

Pye wrote out the specifications for what they needed, but couldn’t get them made reliably and cheaply. They turned to Philips who took Jonker’s ideas and added some items needed for this application, producing the EF50 — a pentode. The resulting TV set (see page 199) had a range of about five times the older sets.

Construction

Old tubes used a difficult process called pinching to seal the end of a glass tube with the leads running through it. The pinch formed an inverted V shape where the bakelite base of the tube fit the wide part of the V and the wires within entered the tube through the point of the V.

This had several problems. As more wires had to pass through the pinch, they had to get closer together. That increased stray capacitance. Worse, the distance from the bottom of the V to the top of the V meant wires had to be relatively long which added inductance. Finally, the size of the V — often half the total length of the tube — was preventing tubes from getting smaller, hindering the development of portable equipment.

One way to solve this was to build the tubes from metal instead of glass, with some connections going through the top of the tube. However, these tubes were expensive to manufacture in quantity and designers did not like having to wire to the top of the tube. The Stahlröhre bucked the trend, putting the tube components in horizontally to decrease wiring to the base and using no top connections. However, again, the cost to manufacture was high. The 1934 acorn tube was all glass and used two parts sealed together with short leads but were also known to be expensive to produce.

Philips, Pye, and the War

When the Dutch military first asked Philips for tubes around 1918, they declined; Gerard Philips though radio had little practical value. It would be 1923 before Philips decided to use its expertise in light bulbs to produce radio tubes. By 1938, Jonker’s work was circulating and in 1939 there was even an article about it in Wireless Engineer.

By the time Pye came looking for high-frequency tubes, Philips was ready due to the earlier work. The Pye receiver used six tubes and required some tweaking, including the addition of a metal shield.

Meanwhile, there was war. The Battle of Britain was in 1940 and the military was busy in 1939 working on RADAR that also operated at high frequencies. This RADAR — and the command and control strategies used with it — would be key to winning the upcoming battle. The team working on airborne RADAR apparently only had one receiver good enough to get results. Then they received a tip that Pye had an excellent receiver that worked in the same frequency range. This became the basis for Britain’s RADAR sets through the war. About 60% of all Pye TV IF strips wound up in British RADAR sets.

The big problem was that by 1940 the Netherlands was in German hands. The production line needed to be moved to Britain, and when the HMS Windsor took the escaping Dutch government to England, the Philips family was also onboard with the diamond dies needed to produce the fine tungsten wires used in the EF50 tube.

After the war, the EF50 would find a home in many oscilloscopes and radio receivers. This was both because of its superior frequency ability and the availability of war surplus. Others would also produce the tube including Marconi-Osram (as the Z90) and Cossor (63SPT). Mullard produced the tube using the original Phillips equipment and both Rogers and Sylvania also produced a version.

Nuvistors

This type of tube would be the king of the hill for RF work until 1959. That’s the year RCA introduced the nuvistor — a metal and ceramic tube assembled in a vacuum chamber. These were nearly as tiny as a transistor, low noise, and had excellent performance at radio frequencies. These were found in a lot of gear all the way until the early 1970s including TV tuners, oscilloscopes, and tape recorders.

More Details

There’s a very long and very well-researched history of everyone and everything related to the EF50 if you want to really dig into the details. There’s even a translation of part of the original internal report about it. You can also find similar information and a lot of unique pictures at [Keith Thrower’s] site.

If you like the sound of an old tube radio, the medium wave receiver in the video below uses some EF50s and it sounds great. Want more tube history? Or perhaps you’d rather make your own. Or you can watch how they made similar tubes back in the day.